ABOUT US

Engineering with a difference

DQD Engineering Ltd has been at the forefront of process system design, installation, and maintenance for nearly three decades. Established in 1995, we have played a crucial role in shaping industry standards, contributing to the development of BSP and ASME guidelines.

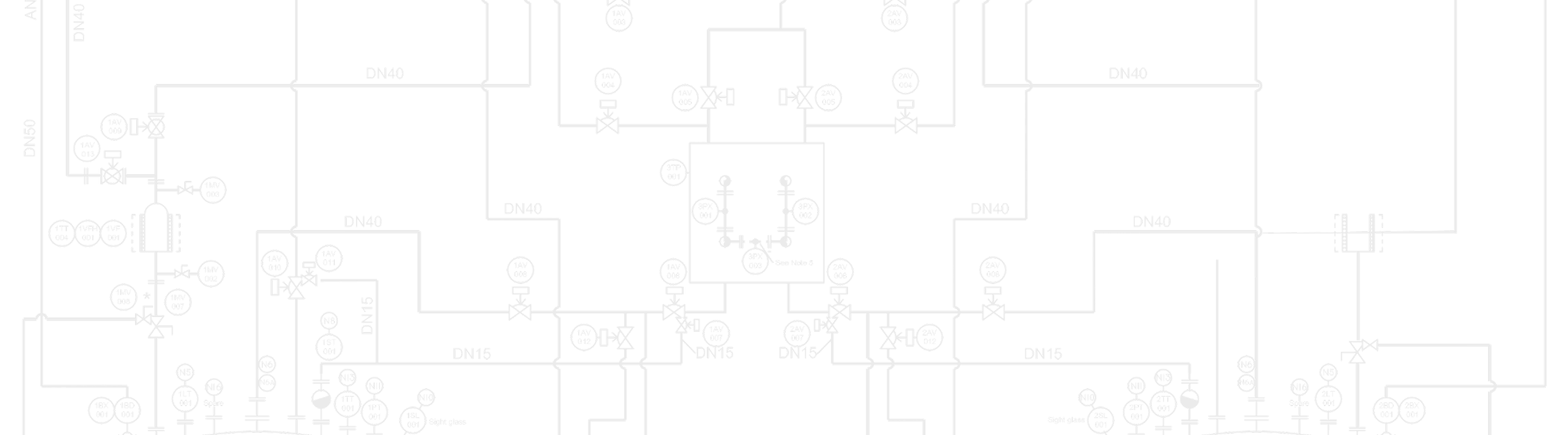

Our expertise lies in delivering high-quality turnkey solutions for RO Generation, Purified Water Storage and Distribution, PSG, Water for Injection, CIP Systems, and more. From concept to commissioning, we ensure seamless integration, adhering to the highest industrial standards, including GAMP, cGMP, and ATEX. Beyond new system installations, we specialize in prolonging the lifespan of existing systems through our comprehensive service and maintenance programs. One of our flagship installations from 2001 ran continuously until 2024, with only a single week of total shutdown for maintenance—testament to our commitment to durability and efficiency.

With in-house expertise in Process Design, ASME BPE Pipework & Vessel Fabrication, Welding, Automation, and Commissioning, we bring engineering excellence to every project. At DQD Engineering, we don’t just build systems—we build reliability, efficiency, and long-term performance.

Supporting systems across

the globe

Get in touch

Fill the form and send a message